With global automobile and truck production of 95 million vehicles (2016), it is not surprising that the automotive segment comprises the largest portion of all weathering testing. And, add to that number the related industries of motorcycles, farm and construction off-road vehicles, military, commercial aerospace, and recreational vehicles (watercraft, snowmobiles, etc.) which all face similar testing needs.

“Act globally, but think (and source) locally” requires testing instruments and services, as well as support, on a global scale; Atlas global footprint is a key attribute to our success as the “go to” automotive weathering technology supplier.

Automotive Exterior Applications

Automotive Paint

Transportation coatings weathering testing is the largest application segment. Monocoat and basecoat/clearcoat (BC/CC) systems of various chemistries dominate with cars and trucks, with gelcoats being common for recreational craft. These include original OEM and aftermarket repair coatings. The changing nature of exterior substrates, such as composites and aluminum as opposed to traditional treated steel, have increased the need for weatherability testing of even previously approved paint systems.

- Outdoor exposure testing of automotive paint is most often performed in subtropical South Florida on a Black Box test rack where the paint panels form the top surface of an open-bottom black colored box, which simulates the dead air space and temperature profile of an automobile body.

- Laboratory weathering of automotive paint systems and coatings is primarily performed to OEM or other (e.g. SAE, VDA, JASO) standard xenon arc test methods with Atlas Ci-Series Weather-Ometers, Xenotest models or SUNTEST XXL+ ST; often a specific model type(s) is designated in the test method or material specification, and defined configurations required. Some legacy testing is performed with now obsolete Sunshine Carbon Arc technology, however commercial lab testing for both xenon and carbon arc is available from Atlas.

- Corrosion testing for transportation paint systems is primarily performed to OEM or other (e.g. SAE, VDA, JASO) standard corrosion test methods with Atlas chambers. Automotive tests usually involve complex cycles of wet/dry periods, temperature cycles, electrolyte sprays, etc. Atlas BCX corrosion cabinets meet many basic cyclic tests, although more complex methods require the CCX cabinet, properly configured for the specific test method(s), and available in a range of size capacities. Atlas offers corrosion testing services for specific test methods.

Fascia Systems and Body Panels

- Painted or molded-in-color (MIC) fascia systems are tested for laboratory weathering using smaller specimens taken from the fascia are tested the same as paint systems.

- Whole fascia and body panels are typically exposed in outdoor environments such as South Florida and Arizona, mounted vertically in their end-use orientation.

Automotive Exterior Lighting

- Lenses and reflex reflectors in head and tail lamp assemblies are exposed outdoors in Florida and Arizona per SAE J576 requirements.

- Exterior lighting assemblies are exposure tested in laboratory xenon arc weathering instruments to OEM requirements. The Ci5000 Series Weather-Ometer is large enough for most lighting fixtures, otherwise outdoor exposure testing is performed to OEM product specifications

Exterior Trim, Graphics, Weather Seals & Gaskets

- Laboratory weathering of exterior trim components, badges, mirror housings, roof racks and weather seals is primarily performed to OEM or other (e.g. SAE, VDA, JASO) standard xenon arc test methods with Atlas Ci-Series Weather-Ometers, Xenotest models or SUNTEST XXL+ ST; often a specific model type(s) is designated in the test method or material specification, and defined configurations required. Some Japanese OEM legacy testing is still performed with Sunshine Carbon Arc instruments (developed in the 1930’s and obsoleted by Atlas in the 1990’s), however commercial lab testing for both xenon and carbon arc is available from Atlas

- The effects of solar thermal load can be tested using Atlas’ metal halide lighting systems, which can be installed in environmental chambers and wind tunnels.

Automotive Glazing

Automotive Glazing

- Outdoor static exposure of windscreens, sidelites, rear windows, sunroofs and panoramic roof systems is usually performed in Arizona and South Florida. The effects of solar control glass on cabin interiors is often performed on instrumented full vehicle exposures on follow-the-sun carousels.

- Small test coupon accelerated exposure testing of laminated and tinted glass is also commonly performed on solar concentrators such as EMMA/EMMAQUA at Atlas/ DSET Laboratories site in Arizona.

Under-hood, Drive-train, Wheel Components

- While normally exposed primarily to indirect reflected solar radiation, polymeric under-hood components such as hoses, wiring, belts and polymer housings, and are often tested to xenon arc weathering standards to OEM specifications.

- Metallic under-hood, drive-train, wheel and brake components are typically corrosion tested to OEM corrosion test methods. Electrical components such as engine starters and solenoids are typically corrosion tested while operating under electrical power

- Electric Vehicle (EV) and hybrid (HEV) components such as batteries, connector blocks and terminals, drive motors, etc., are corrosion tested as components to OEM test methods. Alternatively, Atlas walk/drive-in custom corrosion chambers for body buck or whole-vehicle exposures are used.*

* Automotive corrosion tests typically involve complex cycles of wet/dry periods, temperature cycles, electrolyte sprays, etc. Atlas BCX corrosion cabinets meet many basic cyclic and all steady-state tests. More complex test cycles require the CCX cabinet, properly configured for the specific test method(s), and available in a range of size capacities. Atlas offers corrosion testing services for specific test methods.

Automotive Interior Applications

Automotive Interior Applications

Instrument and Door Panels, Airbag Covers, Hard Trim

- Instrument panel (IP), door panels and airbag cover materials are tested for lightfastness properties (such as fade, color change, gloss, tackiness, etc.) and degradation caused by solar radiation filtered by automotive glazing, in combination with typically high cabin temperatures and humidity levels. These are primarily tested using xenon arc laboratory weathering instruments to OEM specifications.

- If, required, outdoor testing is typically performed in a controlled azimuth tracking IP/DP Box which simulates the conditions found in the interior of an automobile. Alternatively, “indirect” weathering static exposures expose specimens to natural sunlight through glass.

Carpets, Upholstery, Headliners

Carpets, Upholstery, Headliners

- Textiles are primarily tested for lightfastness using xenon arc laboratory equipment OEM specifications.

- Textiles may also be tested in an IP/DP Box or “indirect” weathering static exposures which expose specimens to natural sunlight through glass, per OEM requirements.

Interior Electronics

Interior electronics include instrument cluster displays, radio and entertainment systems, navigation, driver information and driver assist displays, cellular and wi-fi, etc.

- Most automotive cabin electronics are tested using laboratory xenon arc lightfastness equipment to OEM requirements. Electronics for motorcycles, etc., must typically meet OEM requirements for weatherability testing.

- New sensor and display technologies in development, such as Driver Assist, Autonomous Vehicle, Heads-Up Display and OLED Instrument Panels, may require additional custom durability testing.

Safety Restraints

Occupant passive safety restraint systems such as seat belts must meet governmental, industry and/or OEM requirements for light/UV exposure and corrosion testing as well as flammability resistance.

- In the USA, FMVSS 209 - Seat Belt Assemblies - Passenger Cars, Multipurpose Passenger Vehicles, Trucks, and Buses require testing to UV exposure to ASTM G23 Type E—Single open-flame sunshine carbon-arc lamp apparatus. Atlas provides commercial exposure testing to this requirement. In other countries, testing with xenon arc equipment or fluorescent sunlamp (UVTest) devices may be required.

- FMVSS 209 requires corrosion testing to ASTM B117 - Standard Practice for Operating Salt Spray (Fog) Apparatus, which can be met with any Atlas SF, BCX or CCX series corrosion cabinet. Also available from Atlas as a commercial testing service.

Flammability Testing

- The Atlas HMV Horizontal Motor Vehicle flammability test chamber meets FMVSS 302 – “Flammability of Interior Materials – Passenger Cars, Multipurpose Passenger Vehicles, tracks, and Buses (Effective 9-1-72). This standard specifies burn-resistance requirements for materials used in the occupant compartments of motor vehicles, and other standards based on FVMSS 302.

Large Scale Solar Simulation

Atlas Custom Systems is a leader in custom large scale full spectrum solar simulation and solar-thermal load lighting systems which can be integrated into walk/drive-in environmental chambers, wind tunnels, etc. Atlas custom designs lighting solutions for weathering or solar heat load testing, including the mounting and control systems to customer requirements using proprietary Atlas modeling software.

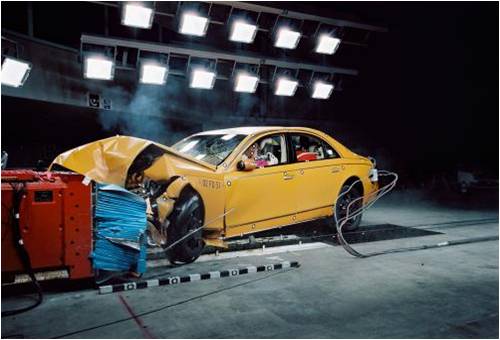

Crash Test Lighting

Crash Test Lighting

Since 1976 Atlas Custom Systems automotive crash test lighting systems for high speed photography have been recognized around the world for their quality and performance.