Water droplets on a vehicle’s exterior

It is no secret that moisture is a major degradation mechanism for many materials. Relative humidity, rainfall, and one-off applications of water to a material’s surface all contribute to degradation in their own ways. This was recognized by Bill Lane, a member of the founding family of Atlas, through the works of Fred Stieg Jr., a paint and coatings researcher, that were published throughout the 1960’s. Stieg’s paper titled “Accelerating the Accelerated Weathering Test” from 1966 and his subsequent paper “The Dew Cycle Weather-Ometer® Re-evaluated - A Literature Review” in 1975 led to the development of the Atlas Dew Cycle Weather-Ometer®, a modified Sunshine Carbon Arc instrument with rack spray that was equipped with a chiller to enhance the formation of dew on the surface of samples under test.

The effectiveness of the Dew Cycle, as documented by Stieg, is exemplified when he stated:

“In a recent article, ‘The Dew-Cycle Weather-Ometer® Re-evaluated - A Literature Review’, appearing in Journal of Paint Technology, a comment was made that the original concept of the ‘dew cycle’ was never expected to become a standard method of test for the accelerated weathering of coatings.

My 1966 article ‘Accelerating the Accelerated-Weathering Test’ was actually intended as a progress report on what might be accomplished to improve the performance of existing accelerated-weathering equipment if some thought was given to the clues provided by earlier investigations, and some attention paid to the relatively simple experimental technique of working with only one variable at a time.

Regardless of that intention, the ‘dew cycle’ was sufficiently novel, the acceleration that it provided sufficiently great, and the claims for its correlation with exterior exposures in Florida sufficiently impressive, to result in the adoption of the test method, as published, by a large segment of the coatings industry - a segment that had been impatiently waiting for any accelerated-weathering test capable of predicting the exterior durability of modern high-performance finishes within a reasonable period of time. Many found the Dew-Cycle Weather-Ometer® ideal for their purposes; others did not.”

Stieg is credited with being the father of the “Dew Cycle”, which was then formally documented in a standard in 1974 as ASTM D3361. This standard is still around with the last revision occurring in 2018. It continues to correctly specify rack spray only (no front spray) in the dark cycle.

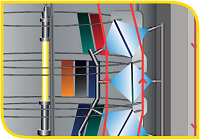

Example of front and back spray in a Ci Weather-Ometer®

This method was also recognized by the military, and its effective use was documented in an article for the Navy by Peter J. Hearst titled “Protective Properties of Coatings as Measured by the Dew-Cycle Accelerated Weathering” in 1970.

In an article from 1974 titled “An Appraisal of Artificial Weathering Methods for Assessment of the Durability of Paint Films, Correspondence” in JOCCA, C. E. Hoey and H. A. Hipwood document that there were efforts to translate the “Dew Cycle” for use in a xenon instrument. An editor’s note found in the Autumn 1975 issue of Atlas SunSpots (Vol. 4, Issue 10) states:

“The ‘Dew Cycle’ as defined by Stieg, and now described in ASTM D3361-74, can be obtained only in unfiltered Type EH units (Models XW-R and XW-WR Weather-Ometers®). A proposed ASTM Recommended Practice provides for a ‘Dew Cycle’ using quartz filtered xenon arcs in place of unfiltered carbon arcs. Programmed controlled humidity, rack spray, and dark cycles are prerequisites for all ‘Dew Cycle’ instruments.”

The fate of this proposed xenon test is unknown. However, US automotive OEMs recognized the value of the inclusion of a “Dew Cycle” in their new method, which they called SAE J1960.

SAE J1960, as originally published in 1989, implemented the “Dew Cycle” correctly. Clause 5.1.7 states, “Install a #180 cam, which provides 120 min of light and 60 min of dark in the following cycle: 40 min of light followed by 20 min of light and front specimen spray, followed by 60 min of light, followed by 60 min of dark with back rack spray and repeating.” This cycle was still correct in the 2001 revision, which was the last revision made before the publication of its replacement, SAE J2527.

When SAE J2527 was first published in 2004, Clause 6.4 deviated from SAE J1960 and specified the cycle as:

Note that both front and back spray are specified in the dark cycle of SAE J2527, whereas only backside spray was specified in SAE J1960. Common sense should tell you that running both front and back spray in the dark phase hinders the formation of dew on the sample surface because the front side spray would effectively wash away any dew accumulation. So, why was front spray added in SAE J2527? The addition of front side spray in SAE J2527 was nothing more than a technical error made by members of the committee. This error also made its way into the last revision of SAE J1960 in 2003 before the standard was cancelled in 2008.

If the “Dew Cycle” provided good correlation to natural weathering exposures, why did its popularity wean? Unfortunately, there is no solid answer for this, but it is speculated that from the late 1980s until the development of ASTM D7869 in 2013, the industry was primarily focused on light rather than moisture. However, there seems to be renewed interest in moisture in the industry and this could be a good time to rehash the rack spray debate to hopefully show the true benefits of this option that were once realized in the 60s and 70s.

To learn more about automotive material testing, check out our free recorded Atlas Online Seminar.

In addition to this, check out Atlas’ complete list of free online seminars.