Optical Lens Design and Materials

Optical Lens Design and Materials

Optical lenses are used for eye wear, optoelectronic devices, cameras, photography, and many more applications. They usually come along as high-tech multi-layer systems, composed of different polymer materials. The top layer is a transparent protective coating which blocks UV and moisture. To protect everything underneath, this layer must be highly scratch-resistant.

Schematic optical lens design. Image courtesy of ZEISS.

For the top layer, fluoropolymer-based coatings and similar types are applied, all of course tested and selected for outstanding non-yellowing properties. Typical materials for the base layers are PU/PUR, PC, acrylates, and allyl compounds.,

Prior to the launch of each new lens system, thorough durability testing needs to be done against mechanical and weather stresses. Yellowing of the transparent layers must be avoided. Finally, key stresses must be identified, that can cause delamination of the protection coating or the adhesion/hard layer.

Durability Testing

Durability and weathering testing aim to cover the accumulated impact on optical lenses over the course of two years. Stress factors are:

- Mechanical: dry cleaning, falling

- Climatic: solar radiation, heat, water

- Chemical: cleaning with water, glass cleaners, sweat

ISO 8980-4 for Anti-Reflective Coatings

When it comes to the climatic stresses, ISO 8980-4 “Specifications and test methods for anti-reflective coatings” is often the first standard test to be explored, if suitable to replicate all failures as observed in the field.

The first option in this standard describes a

- fluorescent-UV (FL-UV) test using water condensation at 45°C for 4 hours,

- followed by UV (UVA-340) exposure at 0.85 W/m2 at 45°C for 4 hours.

The second option describes continuous irradiation for 16 h with a xenon-arc weathering device:

- Continuous light

- Weathering testing incl. wetting by water immersion or water spray at ambient temperature for 5 minutes every 30 minutes

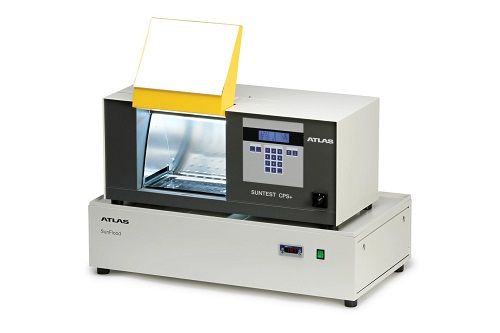

Atlas SUNTEST CPS+ with water immersion unit.

Xenon-Arc vs. Fluorescent-UV (FL-UV) Weathering

From feedback with lens manufacturers, we know that even a 240-hour FL-UV test is not a fully reliable weathering test. Xenon-arc weathering has either been added or replaced their FL-UV test.

Why is xenon-arc weathering better suitable for optical lens testing? The answer is simple: FL-UV testing does not realistically cover the UVA long-wavelength range (350 - 400 nm), which is often critical for optical lenses. “Activation spectra” indicate the most photo-sensitive wavelength regions for a polymer. Polyurethanes, polyarylates, and several other polymers have activation spectra with strong bands inside this UVA-range.

The result: There is a risk of product failures such as yellowing or delamination in the field, even if the lenses pass the accelerated FL-UV test - so called false positives.

The risk of false positives is avoided by using the highly realistic full-spectrum (295 - 2500 nm) xenon-arc devices such as the SUNTEST CPS+ and XLS+, which are frequently used for this application.

More Information

The applications for coated lenses spread from lenses for eye wear, to lenses for optical devices. Furthermore, related applications such as electronic displays also require UV and moisture blocking coatings. Consequently, there are further testing standards tailored to the specific application.

Did we miss important details? Do you want to discuss your needs and requirements? Do not hesitate to contact us. The Atlas team is always here to answer your weathering testing questions.

Check out the SUNTEST series for static horizontal exposures of 3-D products.